Clemco 10 cu ft Classic Blast Machine Model 3661 with Flat Sand Valve (FSV) - Stationary 1-1/4 inch Piping - With TLR-300 Remote

-

Detail

High-performance, versatile blast cleaning system removes contamination, corrosion, mill scale, and coatings from most surfaces. Produces a uniform surface texture, and creates a surface profile to increase bonding for coatings.

Features

- Full Flow Stainless Steel Teflon-Sealed Ball Valves With Brass Body

- Semi-Elliptical Head For Larger Storage Of Abrasive

- Urethane-Coated Pop-Up Valve With External Sleeve For Long Wear Life & Fast Pressurization

- Large Inspection Door For Easy Access To Inside

- Heavy-Gauge Construction Pressure Vessel Fabricated For Rugged Field Service

- Built To ASME Standards

- Conical 35 Degree Bottom Ensures Total Use Of Abrasive & Uninterrupted Abrasive Flow

- 45 Degree Abrasive Flow Into Air Stream

- Heavy Duty Piping Assembled Tightly Against Tank Avoids Unnecessary Protrusions

- Flexible Pusher Line Guarantees Air Flow Without Pressure Loss

- Mounted On Two Heavy-Duty Rubber Wheels For Easy Portability

Requirements for Operation

These items are required but not included with this equipment:- Clean, dry, compressed air of sufficient volume to maintain desired pressure at the nozzle. Refer to Air Consumption Chart in Blast Off 2 booklet (publication stock no. 09294).

- Minimum of 50 psi needed to close the pop-up valve and pressurize the blast machine.

- OSHA-required remote control system that interrupts blasting if operator should lose control of the nozzle when blast machine is pressurized.

- NIOSH-approved, type CE, supplied-air respirator.

- Grade D breathing-air supply as defined by Compressed Gas Association Commodity Specification: G-7.1 (Refer to www.cganet.com).

- Abrasive blast media specifically marketed for abrasive blasting and appropriate for your application.

- Appropriate blast suit, work boots, hearing and eye protection.

Description of Operation

The operator controls blasting from a remote control handle at the nozzle. Pressing the handle starts blasting; releasing it stops blasting. The blast machine contains abrasive and meters it into the compressed air stream.Advantages

- Yard portable, industrial-quality blast machines manufactured to ASME code.

- 1-1/4-inch piping allows up to 50 percent more air flow when compared with 1-inch piping.

- Industrial-quality valves, piping and fittings designed to maximize air flow and minimize energy required to operate the system.

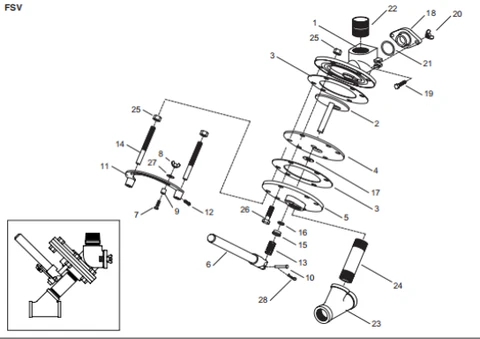

- FSV abrasive metering valve maintains smooth, consistent, adjustable media flow. Model 2443 Lo-Pot has a LPV abrasive metering valve.

The FSV, an original Clemco design, is the triedand-true work horse of the industry. It is among the most imitated Clemco components. It is standard on machines from 2-cubic feet to 20-cubic feet capacity

NOTE: All have pneumatic pressure-release remote controls except as specified. Electric remotes should be used when blast hose is 100ft or longer. For Soft King and Pool Pal, see Aerolyte tab.

-

Customer ReviewsNo comments